An automatic painting line is an automated system designed to carry out the paint spraying process, aiming to achieve faster and more efficient results. Automatic painting lines are widely used in industries such as home appliances, electronics, and especially in the automotive and motorcycle sectors, where they help ensure consistent quality across the entire production line, increase productivity, and reduce costs.

But should every business invest in an automatic painting line? Let’s explore the details of this system with PWP Solution in the article below!

A well-painted vehicle not only enhances its aesthetic appeal but also serves to protect the vehicle from environmental impacts and shield the frame. For companies in the automotive and motorcycle industries, delivering a uniform and standard-compliant paint layer also reflects the brand’s credibility.

To achieve the desired coating, the painting line goes through multiple stages before the product reaches the customer. Below are the basic steps in an automatic painting line:

Loading the product onto the line: The product is placed on a conveyor belt to enter the painting area.

Surface cleaning: To ensure quality coating and increase paint adhesion, it's essential to remove sand, dust, rust, and metal shavings.

Drying: After cleaning, the product may still contain solvents or impurities, so drying is needed to ensure the surface is in optimal condition.

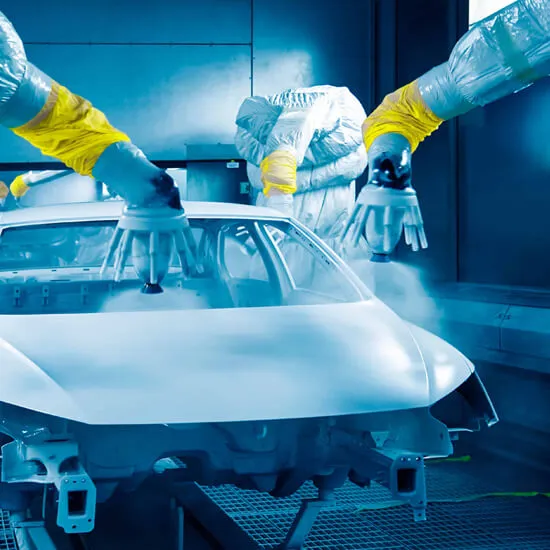

Paint spraying: This is the most important step, where paint is applied to the surface. The painting process usually takes place in a closed environment with controlled temperature, light, and humidity. The spray booth also includes ventilation and leftover powder/paint exhaust treatment systems.

Final drying: After painting, the conveyor moves the product to the drying area. The drying process must be managed carefully in terms of temperature and time to ensure the paint layer hardens and shines properly.

With its professional, multi-stage workflow, the painting line offers a variety of benefits that help businesses reduce manual labor while improving quality and productivity. Here are the most notable advantages:

All products undergo the same process, steps, and operations, minimizing discrepancies. Parameters are clearly programmed and calculated, reducing operational errors.

An automatic painting line can replace almost all manual labor, reducing human involvement and lowering labor costs over time. It automates each stage of the process, ensuring high consistency and productivity.

Integrated inspection and monitoring systems ensure smooth operation and product consistency, minimizing repainting or quality issues. With greater output and reduced investment per unit, overall production costs are also lowered.

Excess paint from uncontrolled spraying by manual workers can increase VOC emissions. Automatic lines feature systems to treat excess powder and exhaust, minimizing air pollutants and protecting workers’ health.

Despite the many benefits it brings, the automatic painting line also comes with some drawbacks that businesses should consider:

The system requires advanced machinery and integrated monitoring and control systems, resulting in a high initial cost. To maintain smooth operation, regular maintenance and servicing are also necessary.

Due to the high cost and maintenance requirements, automatic painting lines may not be economically viable for businesses that produce low volumes or a variety of different products.

Automated systems are usually designed to specific standards, making it difficult and costly to modify the production process - such as changing paint types, colors, or switching to a new product line. Therefore, automatic lines are best suited for large - scale operations producing high volumes of a single product. For small and medium enterprises, a semi - automatic painting line may be a more practical and cost - effective solution.

Automatic painting lines in the automotive and motorcycle industries can bring substantial economic benefits and significantly improve product quality. However, businesses must carefully consider investment costs, flexibility, production needs, and available workforce before implementing such systems. If you're interested in PWP Solution’s automatic painting lines, don’t hesitate to contact us for expert consultation and a customized quote!