Weld cracking is one of the most severe defects in the welding process, directly affecting the strength and safety of the structure. This issue often arises due to residual stress, improper materials, or inadequate welding procedures.

Cracks can appear immediately after welding or develop over time during use, making them difficult to detect and repair. Understanding the causes and formation mechanisms of cracks is key to effective prevention. In this article, let’s join PWP Solution in exploring the different types of weld cracks, what causes them, and how to effectively address these issues!

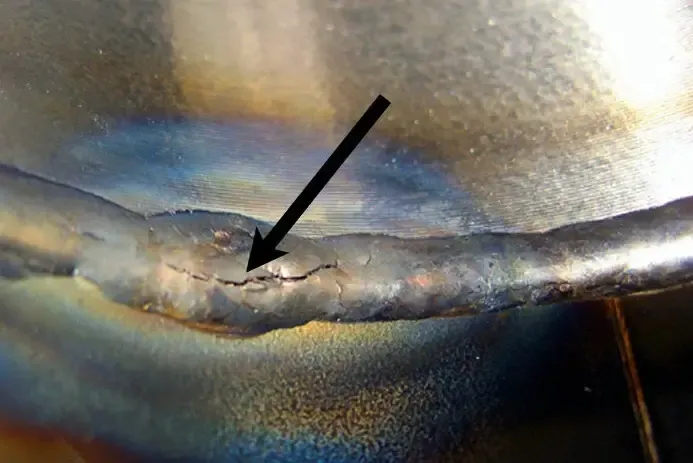

Weld cracking refers to the appearance of cracks on or near the welded metal area, reducing the strength and performance of the weld joint. These cracks can occur during welding, immediately after welding, or after a period of use when the structure is subjected to loads or environmental impacts.

There are numerous reasons why weld defects occur, directly impacting product quality. Although cracks may initially be small, they can propagate during use, eventually compromising the weld joint's integrity.

The first step is to identify the location of the crack and determine whether it is a hot or cold crack.

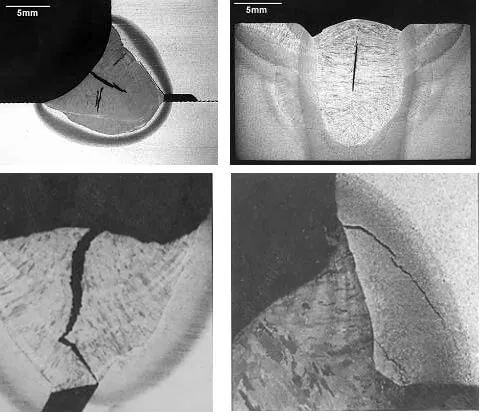

Cracks by location can be categorized into four main types: transverse or longitudinal weld cracks, cracks within the weld, and cracks between different weld seams.

Longitudinal cracks occur when low melting point impurities concentrate at the center of the weld during solidification.

Cause:

Incorrect filler material used during welding.

High levels of residual stress within the weld joint.

Weld metal cools too quickly.

Poor weld design or weld arrangement.

Solutions:

Select the correct welding material before starting.

Preheat the base material and maintain heat post-welding to reduce cooling rate.

Use a proper weld design and stagger the weld joints to reduce stress concentration.

Transverse weld cracks appear perpendicular or nearly perpendicular to the weld axis. These cracks can develop in the weld metal, heat-affected zone (HAZ), or at the interface between the base metal and weld metal.

Causes:

Incorrect welding material selection.

Rapid cooling of the weld.

Weld size too small relative to the joint.

Solutions:

Carefully select appropriate welding materials.

Preheat the workpiece before welding.

Increase welding current and use larger electrodes during the welding process.

Hot cracks occur during the solidification process at high temperatures, before the weld metal fully transitions to a solid state. Also known as solidification cracking, these cracks are usually visible to the naked eye and affect both the aesthetics and structural quality of the weld.

Solutions:

Preheat the material and maintain heat after welding to slow down the cooling rate.

Choose welding rods, wires, and fluxes with low sulfur and phosphorus content to reduce brittleness.

Avoid welding in extremely cold or windy conditions to prevent rapid cooling.

Cold cracks (also known as delayed or hydrogen-induced cracks) form after welding is completed, once the weld and HAZ cool down below approximately 200°C. They may not become visible until hours or even days later. This type of crack is especially dangerous as it is hard to detect and can silently propagate, causing structural failure over time.

Mains causes:

High hydrogen content in the weld.

Rapid cooling causes brittle microstructures to form.

High residual stress due to poor welding procedures or structural design.

Just like with hot cracks, to prevent cold cracks, welders should preheat materials, maintain post-weld heat, choose appropriate filler materials, and strictly control the welding process.

Weld cracking significantly affects the strength and safety of welded structures. Identifying the root causes and applying effective preventive measures are key to improving product quality. Therefore, it's crucial to strictly follow welding procedures, use suitable materials, and conduct regular quality inspections throughout production.

Only by properly controlling weld cracking can businesses ensure optimal product performance and reliability. If you’re experiencing issues and need expert guidance, don’t hesitate to contact PWP Solution for the best support and consultation!