Robot sơn ô tô hiện đang là một trong những giải pháp tuyệt vời giúp mang lại độ chính xác cao và nâng cao chất lượng sơn đồng đều cho sản phẩm. Sản xuất ô tô vốn là ngành đòi hỏi cao về tiêu chuẩn đầu ra khắt khe và yêu cầu chất lượng chặt chẽ để tất cả sản phẩm trong dây chuyền có độ đồng nhất với nhau. Vậy robot sơn ô tô sẽ là giải pháp tối ưu như thế nào cho công đoạn sơn của doanh nghiệp linh hoạt hơn? Cùng PWP Solution khám phá những lợi ích vượt trội mà nó đem lại ở bài viết dưới đây nhé!

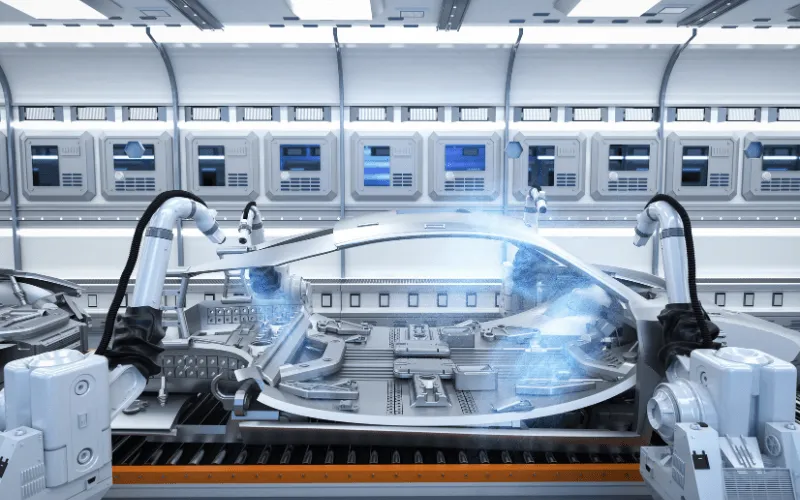

An automotive painting robot is an automated device programmed to perform paint spraying with high precision while maintaining the best quality standards. It typically consists of:

A flexible robotic arm that can access every surface of the car requiring paint.

A spray system that ensures a smooth, even, and aesthetically pleasing paint finish.

With the continuous advancement of science and technology, the introduction of painting robots has transformed traditional painting methods, reducing reliance on manual labor and increasing competitiveness. So, how does implementing painting robots in production lines benefit businesses?

Painting robots apply coatings evenly across all surfaces, including hard-to-reach corners, improving the finish quality and overall visual appeal of the vehicle.

Traditional painting methods require many workers to operate continuously. However, with automotive painting robots, the entire painting line is automated, and only one technician is needed to control the system via computer. This enhances work efficiency and makes production more sustainable.

Paint contains highly toxic chemicals that can pose health risks with prolonged exposure. Painting robots take over these hazardous tasks, minimizing the risk of accidents and protecting workers from harmful substances.

Painting robots use precise spraying technology that accelerates the painting process, reduces overspray, and limits emissions during production. This contributes to environmental protection and reduces industrial pollution.

In the automotive manufacturing sector, painting robots are widely used in several key areas:

Car body painting: Ensures a durable, attractive paint layer that protects against environmental damage.

Chassis painting: Enhances durability and corrosion resistance of the vehicle frame.

Metal and plastic parts: Improves the quality and aesthetics of components and accessories.

Mechanical parts and equipment: Increases longevity and reduces wear and tear of machine components.

Today’s market offers a wide range of automotive painting robots in various sizes and colors. However, choosing the right supplier is essential. PWP Solution is proud to be a leading provider and installer of automotive painting robots in Vietnam.

Highly skilled engineering team: PWP Solution’s engineers have participated in major projects, including paint lines for VinFast and Yamaha.

Comprehensive support: We not only offer optimized solutions but also assist clients in design and manufacturing to build high-quality production lines that meet the strictest requirements.

Warranty and maintenance: PWP Solution offers reliable after-sales service, including long-term maintenance and warranty support.

Automotive painting robots offer high accuracy, ensuring a smoother and more uniform finish compared to manual painting methods. They also help businesses reduce manual labor, boost productivity, and enhance product consistency. With robotic assistance, upgrading and optimizing your company’s paint line becomes more efficient and effective. To learn more about automotive painting robot solutions and receive tailored advice for your business, contact PWP Solution today for the latest consultation!