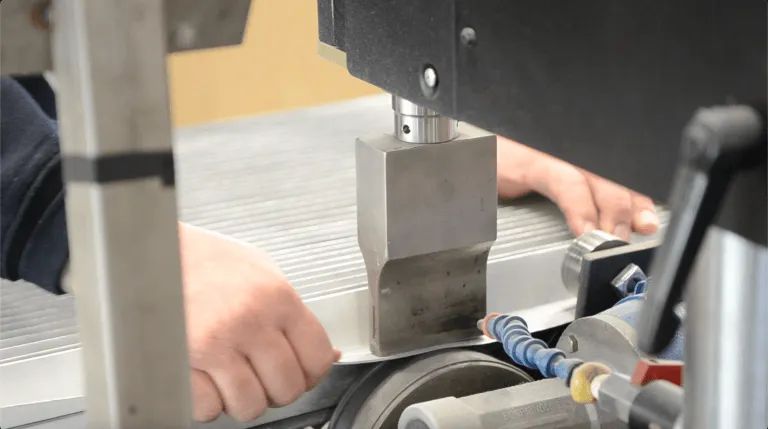

Ultrasonic welding is an advanced welding technology that is increasingly being applied in the field of metal processing. This technique uses high-frequency ultrasonic waves to generate thermal energy, melting and bonding metals without the need for adhesives or soldering materials. Ultrasonic welding offers numerous advantages over traditional welding methods, such as improved product quality, faster production speeds, and enhanced environmental sustainability.

Understanding the benefits and limitations of ultrasonic welding can help businesses assess its potential application in manufacturing, thereby optimizing production processes and improving operational efficiency. Let’s explore the key highlights of ultrasonic welding with PWP Solution in the article below!

Ultrasonic welding is considered one of the fastest and most modern welding techniques in the industry. With a weld time ranging from just 0.1 to 1 second, ultrasonic welding offers significant advantages for businesses aiming to accelerate production and improve product quality. Below are the key benefits of ultrasonic welding in metal processing:

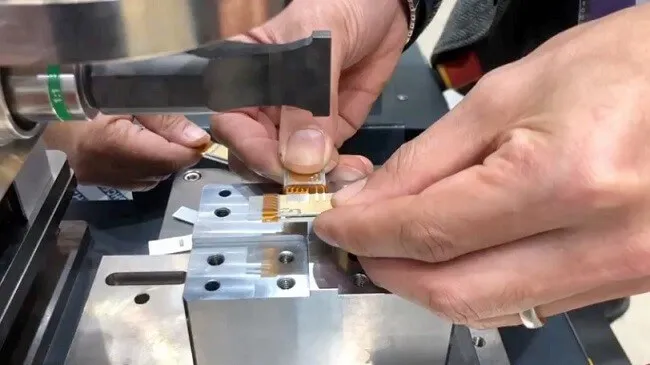

Ultrasonic welding creates uniform welds with high strength and micrometer-level accuracy.

It minimizes welding defects such as porosity, cracks, and deformation caused by excessive heat.

The welding process takes only a few seconds, significantly reducing production time compared to traditional methods.

Ideal for mass production, helping increase output while maintaining consistent product quality.

1.3. No Need for additional materials

Does not require adhesives, solder, or any bonding agents, which helps save costs and reduces environmental risks.

Eliminates factors that may compromise weld strength.

Produces no toxic emissions, uses no harmful chemicals, and consumes less energy than traditional welding methods.

Minimizes environmental impact and aligns with sustainable development trends.

Applicable to a wide range of metals such as aluminum, copper, stainless steel, titanium alloys, etc.

Especially suited for industries that require high precision, including electronics, medical devices, and automotive manufacturing.

Despite its many advantages over other welding methods, ultrasonic welding still has some limitations:

Ultrasonic welding is most effective for metal sheets thinner than 3mm.

Not suitable for thick metal structures or applications requiring high mechanical strength.

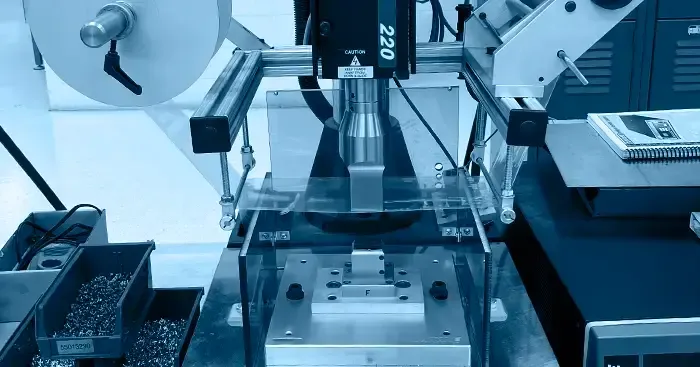

Ultrasonic welding machines are significantly more expensive than traditional welding equipment.

Requires investment in machinery, components, and regular maintenance to ensure stable performance.

Operating and maintaining ultrasonic welding systems demands highly skilled technicians.

Errors in setup can reduce weld quality or damage equipment.

Some metals with poor thermal or acoustic conductivity are incompatible with ultrasonic welding.

Certain alloys with unique crystalline structures may be negatively affected by the process.

Ultrasonic welding is being integrated with artificial intelligence (AI) and automation systems to optimize welding processes.

Advanced sensors are being developed to monitor weld quality in real-time.

Currently applied in automotive, electronics, medical devices, and aerospace industries.

In the future, this technology may expand into areas such as lithium-ion battery manufacturing for electric vehicles and advanced composite material production.

Research institutes and tech companies are focusing on developing more advanced ultrasonic transducers to expand the technology's applicability.

Efforts are being made to improve weld durability and minimize impacts on material structure.

Ultrasonic welding is a cutting-edge metal processing technology that offers high precision, fast production speeds, and environmental friendliness. However, it also presents certain limitations, particularly regarding investment cost and material compatibility. In the context of modern industry, applying ultrasonic welding can help businesses improve product quality, optimize production processes, and reduce environmental impact. If you are considering integrating ultrasonic welding into your products, don’t hesitate to contact PWP Solution for more detailed information!