Cold pressing is a metal processing method that does not use heat and is widely applied in modern manufacturing. Businesses often utilize cold pressing to optimize production processes and ensure the highest product quality. In this article, let's explore the cold stamping method and the characteristics of cold pressing dies with PWP Solution!

Cold pressing is a metalworking technique that uses room temperature and high pressure to shape products into the required form and dimensions. The materials used for cold pressing must have high ductility, resistance to cracking, and good deformation capability.

Common materials used in cold pressing include low-carbon steel, alloy steel, and non-ferrous alloys.

Cold pressing is a metal processing method that does not require preheating. It is widely adopted by businesses to improve product quality and enhance work efficiency. So, what are the advantages and disadvantages of cold pressing in metal processing?

Besides optimizing productivity and improving product quality, cold stamping offers several key benefits:

Despite its advantages, cold pressing has some limitations:

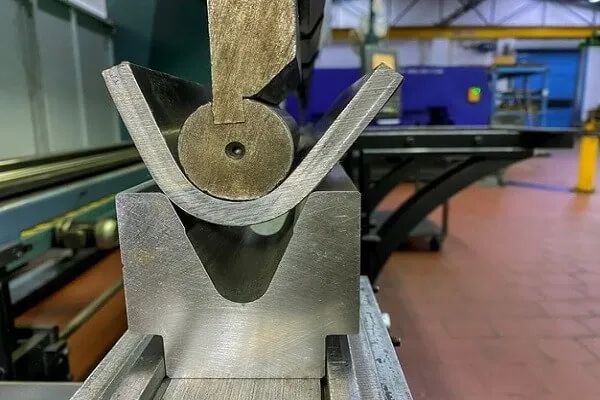

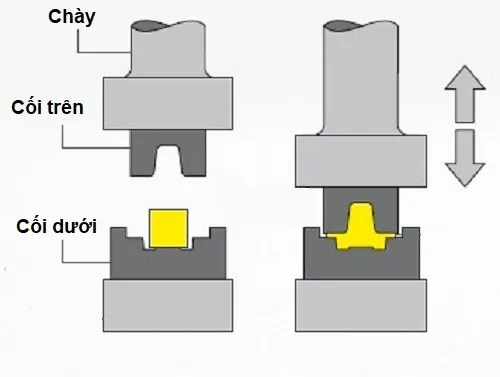

A cold pressing mold is a specialized tool used to shape or cut sheet metal without heating. It ensures high precision, high productivity, and excellent surface quality. A cold pressing mold consists of two main components:

Cold pressing molds are typically made from high-carbon steel (1% carbon content) to provide durability and hardness. In cases where the mold is subject to frequent impacts, low-carbon steel (<0.6%) is preferred for increased toughness.

Choosing the right mold material is crucial for durability and longevity. Below are the most commonly used steel grades for cold pressing molds:

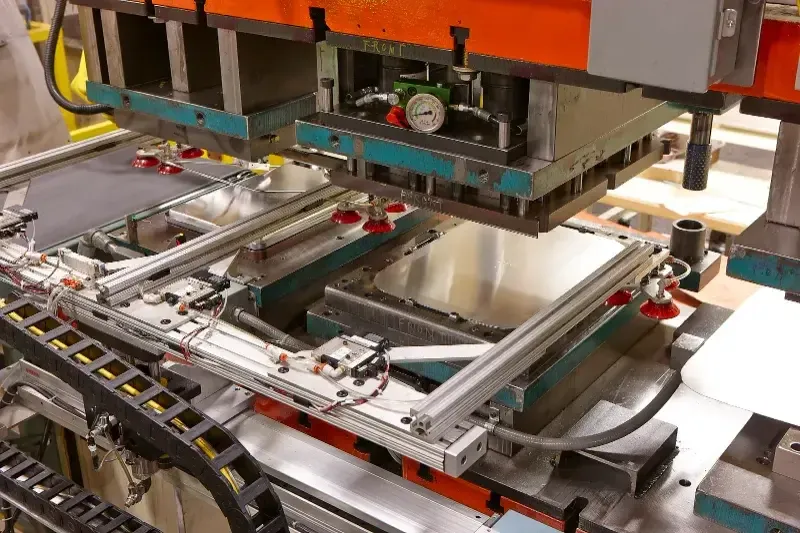

Cold pressing is an ideal method for businesses seeking to enhance product quality and reduce costs. At PWP Solution, we utilize advanced stamping machinery to ensure high-precision products that meet the strictest standards. Our cold pressing process accommodates a wide range of materials, from simple to complex, catering to diverse customer needs.

Cold pressing is a highly effective method that ensures excellent product quality while saving energy and minimizing material waste. As a result, it is widely applied across key industries, including automotive, electronics, household appliances, and construction, due to its high accuracy and production efficiency. If you're interested in cold stamping technology, contact PWP Solution today for expert support!