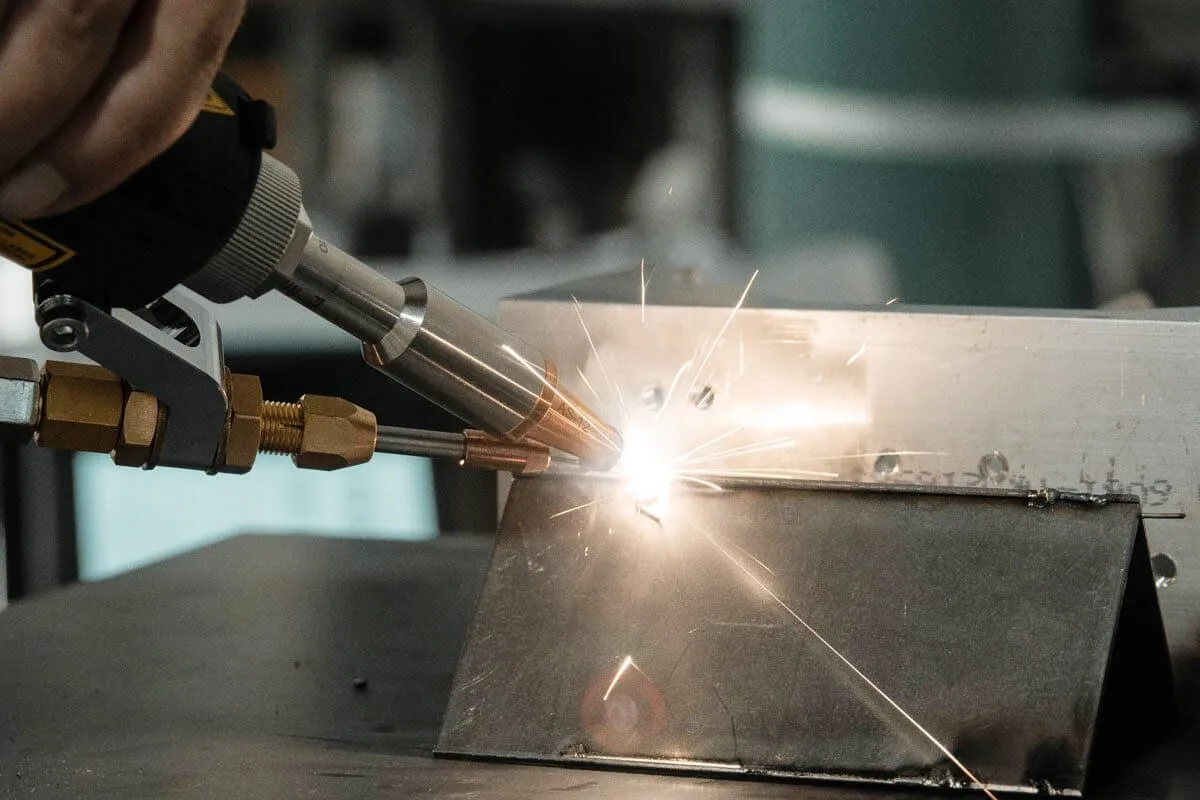

In recent years, traditional welding methods such as arc welding, TIG welding, and MIG welding have remained common choices in industrial manufacturing. However, these methods come with several limitations, including significant thermal distortion, slower processing speeds, and the need for multiple post-welding treatments.

To address these challenges, laser welding has emerged as a modern solution, offering high precision, faster processing, and minimal heat impact. Thanks to these outstanding advantages, laser welding is gradually becoming a trend in modern industrial production. So, what are the key characteristics of laser welding, and in which fields is it applied? Let’s explore the answers with PWP Solution in the article below!

1. What is laser welding?

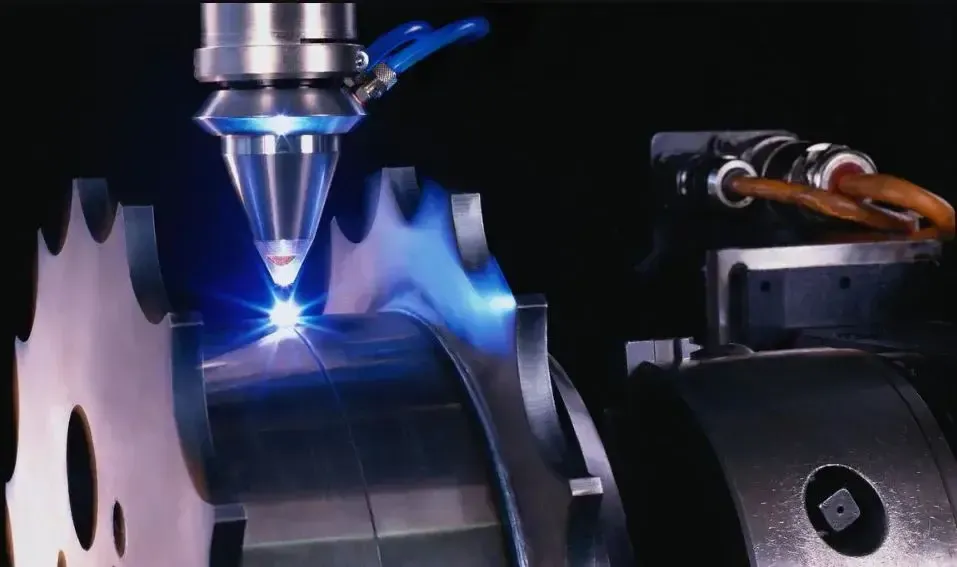

1.1. Operating principle of laser welding

Laser welding uses a high-intensity laser beam to concentrate energy on a small area of the material, generating high temperatures that melt and fuse surfaces together. This process can be controlled by CNC machines or automated robotic systems, enhancing accuracy and operational efficiency.

1.2. Advantages of laser welding compared to traditional welding

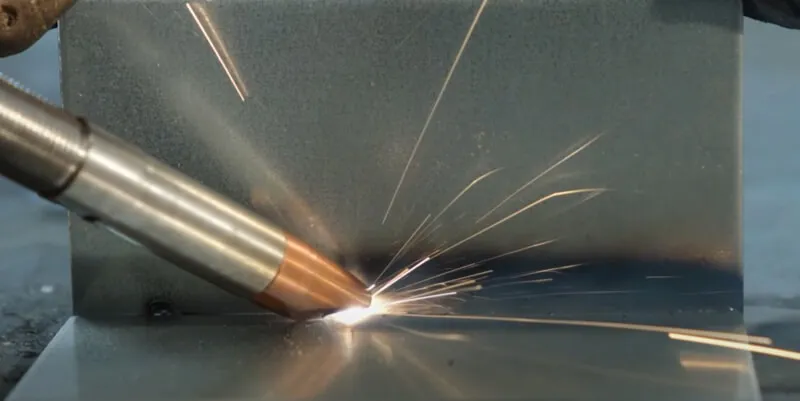

Laser welding is a modern welding method that offers high precision and numerous advantages over traditional welding methods. Below are the standout features of laser welding:

High precision: Enables welding of small, complex components with minimal deviation.

Faster welding speed: Reduces production time compared to conventional methods.

Minimal heat-affected zone: Limits material distortion, helping maintain product quality.

Versatile applications: Capable of welding various materials such as steel, aluminum, titanium, and special alloys.

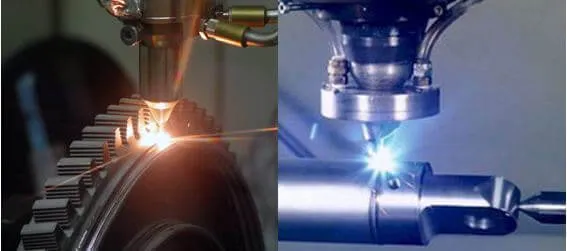

1.3. Applications of laser welding in industry

Thanks to its outstanding benefits, laser welding is used across a wide range of industries. The most common applications include:

Automotive industry: Welding of car frames, engine components, and EV batteries.

Aerospace industry: Welding of heat-resistant and high-pressure metal parts.

Electronics industry: Manufacturing of microelectronic components, phone casings, and lithium batteries.

Medical industry: Welding of surgical instruments and high-precision medical devices.

Thanks to computer-controlled systems, laser welding creates consistent and accurate welds, minimizing production errors

The laser welding process is fast, allowing businesses to increase production volumes without needing to expand labor or production lines.

Laser welding has a smaller heat-affected zone, reducing material warping and cracking - especially important for sensitive alloys.

Laser welding is applicable to metals, plastics, and hard-to-weld alloys, meeting the needs of diverse industrial sectors.

Laser welding is an advanced technology offering high precision, speed, and minimal thermal distortion. However, to ensure weld quality and workplace safety, several key factors must be considered:

Personal protective equipment (PPE): Laser beams can harm the eyes and skin, so welders must wear proper protective gear like goggles and safety clothing.

Fume and gas control: Harmful gases can be released during welding. Use exhaust systems or respirators to ensure safety.

Choose the right laser type: Each type of laser is suitable for different materials and applications, so selecting the correct one is essential.

Clean surfaces before welding: Dirt, grease, and rust can affect weld quality and durability.

Properly fix components: Ensure that materials remain in position during welding to avoid errors and maintain uniformity.

Clean the lens and laser head: After welding, clean these parts to prevent reduced beam intensity or misalignment due to dust or debris.

Laser welding not only improves precision, reduces production costs, and minimizes thermal distortion, but also helps businesses optimize manufacturing processes and enhance product quality. To increase production efficiency, improve product standards, and maintain a competitive edge in the market, many companies are willing to invest in this modern technology. Today, laser welding is opening a new era for the manufacturing industry - paving the way toward smart, efficient, and sustainable production. If you're interested in laser welding technology, contact PWP Solution today to receive personalized consultation for your company's products!