In the metalworking industry, hot pressing and cold pressing are two important techniques that help shape metal according to the requirements of each product. Each method has its own characteristics, affecting product quality, production costs, and work efficiency. Choosing the appropriate pressing method not only optimizes the production process but also ensures durability, aesthetics, and economic efficiency for the business.

So, which materials are hot pressing and cold pressing used for, and what are the differences between these two methods? Let's explore in detail the features of hot pressing and cold pressing technology in the article below with PWP Solution!

1. Understanding hot pressing

1.1. Concept and process

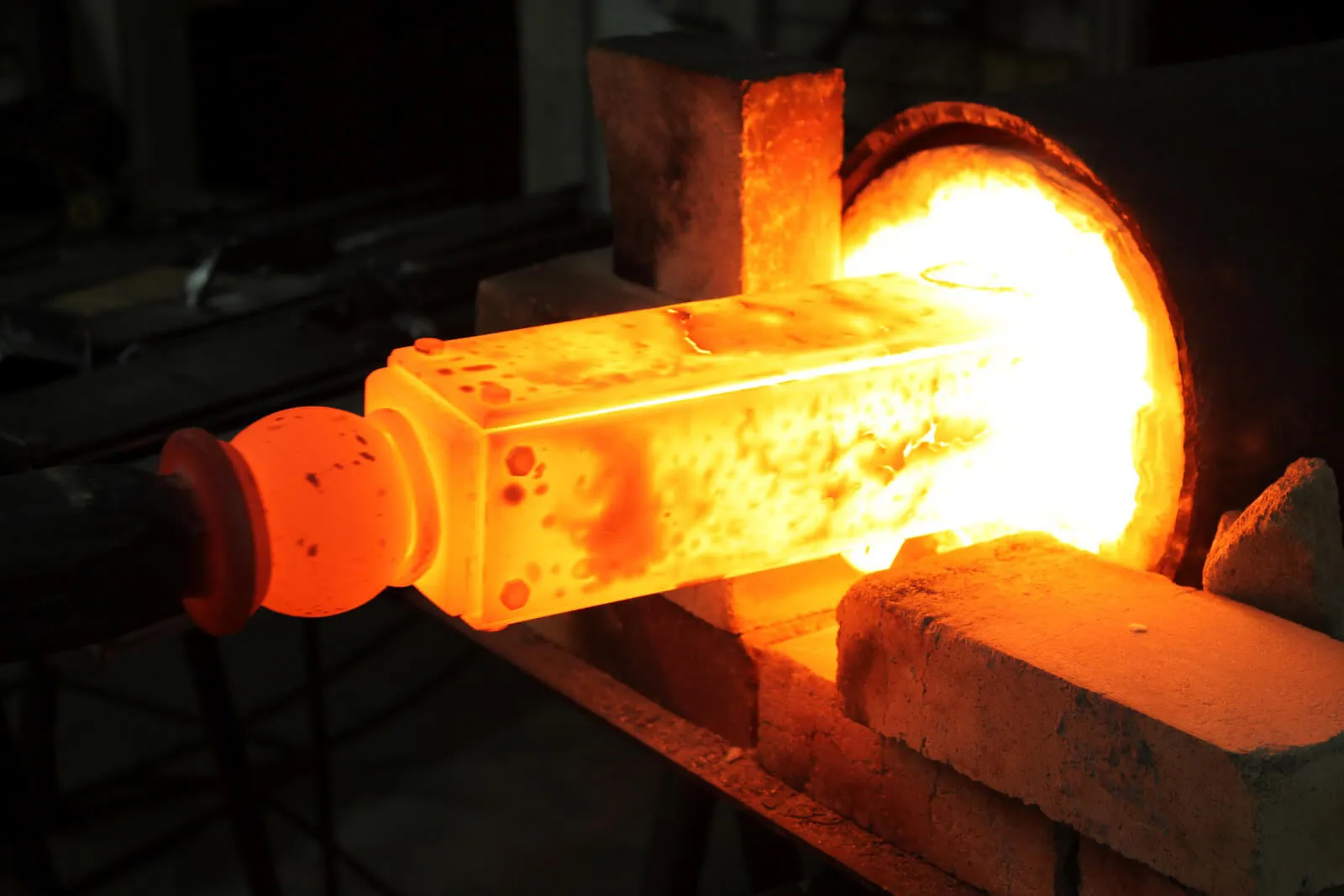

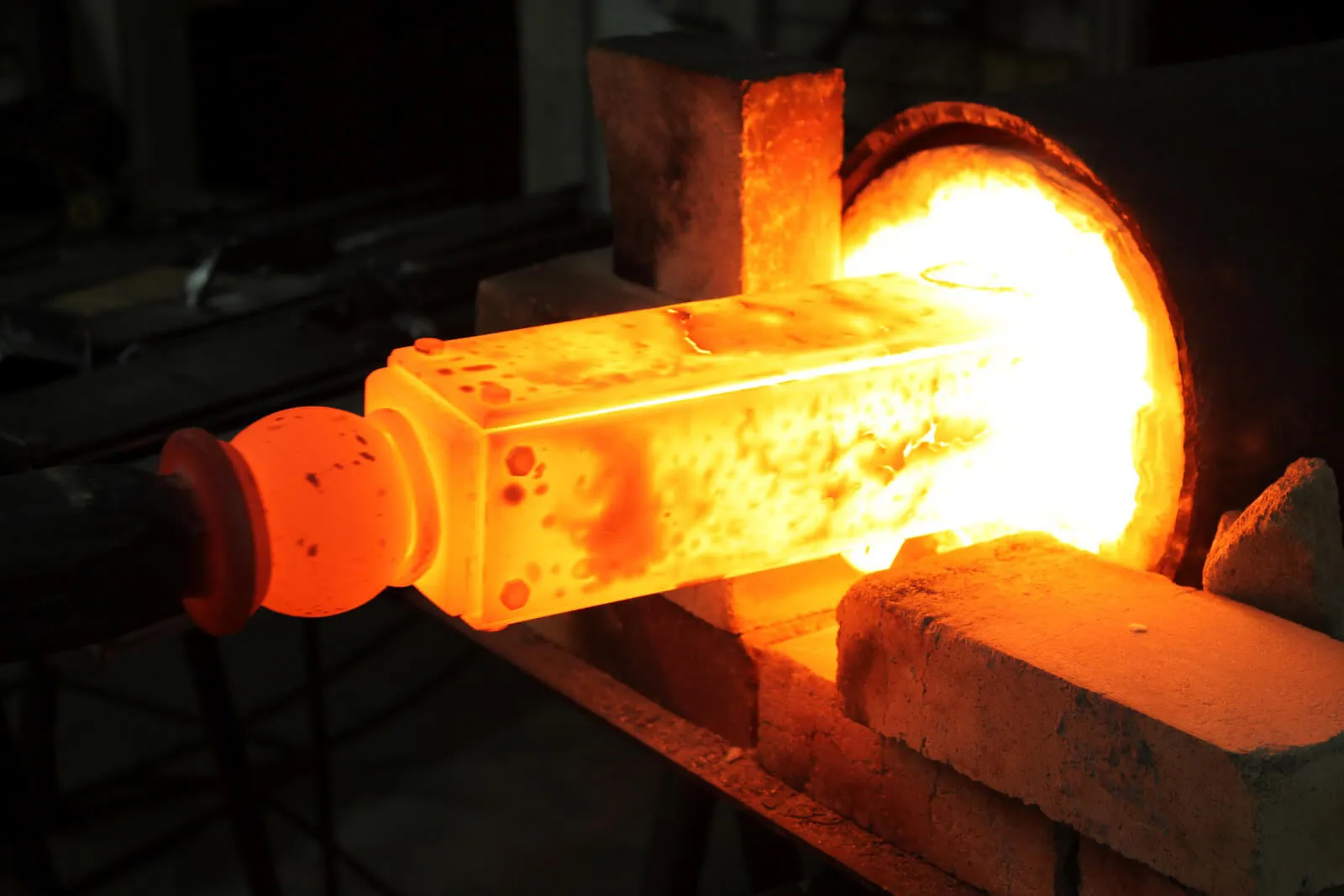

Hot pressing is a metal pressing method performed at high temperatures, typically above 900°C. At this temperature, the metal becomes more malleable, allowing it to be shaped easily using compressive force without cracking.

Hot pressing process:

- Heat the metal to the required temperature.

- Place the metal workpiece into the die and shape it using compressive force.

- Cool the product to solidify the desired shape.

- Finish the product with surface treatment if needed.

1.2. Advantages of hot pressing

- Reduces stress and deformation: Metal in a heated state is easier to shape, minimizing defects such as cracks or die failure.

- Produces high-strength components: Due to material structure changes, hot-forged products generally have superior mechanical strength.

- Allows for complex part manufacturing: Hot pressing enables the production of intricate designs, particularly for thick and complex-shaped parts.

1.3.When to choose hot pressing?

- When manufacturing thick and complex-shaped components.

- When high mechanical strength is required, such as in automotive frames, aircraft parts, and oil & gas industry components.

- When working with hard materials like high-strength steel, titanium, or special alloys.

2. Cold pressing

2.1. Concept and process

Cold pressing is a metal forming method performed at room temperature or with slight heating, without significantly altering the material's structure.

Cold forging process:

- Place the metal sheet into the die.

- Apply high pressure to shape the product.

- Cut, bend, or emboss to complete the details.

2.2. Advantages of cold pressing

- Reduces stress and deformation: Metal in a heated state is easier to shape, minimizing defects such as cracks or die failure.

- Produces high-strength components: Due to material structure changes, hot pressing products generally have superior mechanical strength.

- Allows for complex part manufacturing: Hot pressing enables the production of intricate designs, particularly for thick and complex-shaped parts.

2.3. When to choose cold pressing?

- When manufacturing thick and complex-shaped components.

- When high mechanical strength is required, such as in automotive frames, aircraft parts, and oil & gas industry components.

- When working with hard materials like high-strength steel, titanium, or special alloys.

3. Key factors in choosing hot or cold pressing

- Material type: Thick and hard materials are suitable for hot preesing, while thin or flexible materials work better with cold preesing.

- Design complexity: Complex components with multiple edges are often processed with hot pressing to prevent cracking.

- Production volume: Cold preesing is ideal for mass production, whereas hot preesing is preferred for high-strength products.

- Production cost: Hot pressing is more expensive due to high energy consumption, while cold preesing is more cost-effective but may require additional finishing processes.

4. Applications of hot and cold preesing various industries

Hot and cold preesing are widely used in manufacturing across different industries. The choice between these methods depends on the product’s requirements and characteristics. Below are some common applications:

In the automotive industry:

- Hot pressing: High-strength car frames, door reinforcement bars.

- Cold pressing: Car body panels, metal interior components.

In the aerospace industry:

- Hot pressing: Commonly used in engine parts and aircraft structures.

- Cold pressing: Used in electronic components and lightweight brackets.

In the electronics industry:

- Cold pressing: Device casings, circuit boards, connectors.

5. Conclusion

Both hot and cold pressing play crucial roles in industrial manufacturing. The choice of method depends on factors such as material type, design complexity, production volume, and cost. Hot pressing is ideal for thick, high-strength components, while cold pressing is more suitable for fast, cost-effective, and precise mass production.

Understanding the characteristics of each method helps businesses optimize production, reduce costs, and improve product quality. If you’re unsure whether hot or cold pressing is best for your product, contact PWP Solution for expert consultation!