Metal welding is one of the most commonly applied welding methods today, capable of joining metal materials and creating strong, durable joints. However, metal welding includes various techniques, each with its own characteristics suited for different purposes. So, how do you determine the most effective welding method for your product, and what are the advantages and disadvantages of each method? In this article, let's explore the most commonly used metal welding techniques with PWP Solution!

Metal welding is the process of joining two or more metal pieces together using heat or pressure (or both), often with the addition of a filler material. Once cooled, the weld forms a strong bond, securing the metal parts together.

Today, welding is widely applied in various industries due to the following key features:

There are various welding methods available on the market, each with its own advantages and disadvantages. Below are the five most commonly used welding techniques:

Stick welding is a method that uses an electric arc to melt the electrode and base metal, creating a strong joint. The welder manually performs tasks such as electrode replacement, arc movement, and welding adjustments.

Advantages of stick welding:

Disadvantages of stick welding:

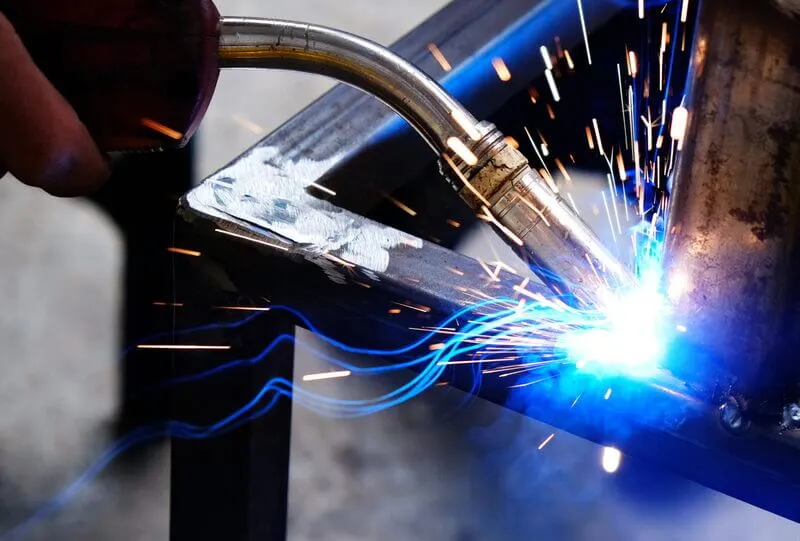

MIG welding utilizes a consumable wire electrode and shielding gas to form the weld. The electric arc between the electrode and base metal is protected from nitrogen and oxygen by an inert or reducing gas environment.

Advantages of MIG welding:

Disadvantages of MIG welding:

TIG welding uses a tungsten electrode and shielding gas (typically Argon) to create precise welds.

Advantages of TIG welding:

Disadvantages of TIG welding:

Similar to MIG welding, MAG welding also uses a tungsten electrode, but a bare wire is continuously fed into the weld, and CO₂ is introduced as the shielding gas.

Advantages of MAG welding:

Disadvantages of MAG welding:

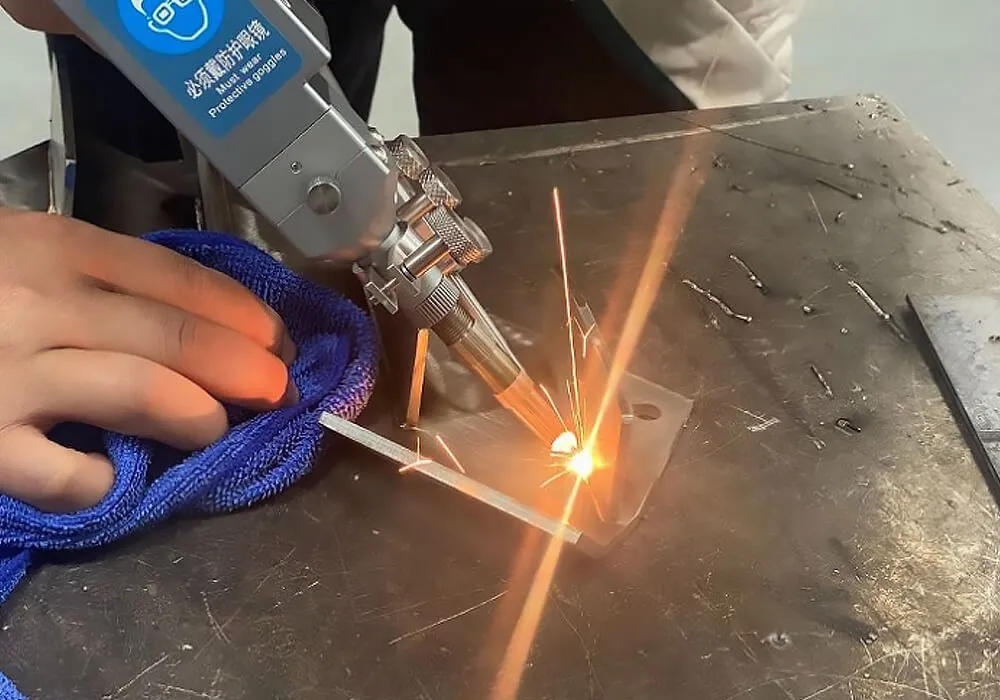

Laser welding is the most advanced metal welding method and is widely used today. It is particularly effective for small, heat-sensitive components like ceramics.

Advantages of laser welding:

Disadvantages of laser welding:

Each welding method has its own advantages and limitations. To choose the most suitable welding technique, consider the following factors:

Below is a comparison table of the most commonly used welding methods:

| Criteria | Stick Welding | MIG Welding | TIG Welding | MAG Welding | Laser Welding |

| Principle | Arc welding with an electrode | Arc welding with wire & inert gas | Tungsten electrode & shielding gas | Consumable wire welding with CO₂ | Sử dụng chùm tia laser |

| Power Source | Electric arc | Electric arc | Electric arc | Electric arc | Fiber laser welding |

| Investment Cost | Thấp | Medium | High | Medium | Very high |

| Weld Quality | Medium | High | Very High | High | Very high |

| Welding Speed | Medium | High | Very High | High | Very high |

| Automation | No | Yes | No | Yes | Very high |

| Applications | Construction, repairs, steel structures | Automotive, shipbuilding, machinery | Aerospace, molds, special materials | Automotive, motorcycles, steel structures | Microelectronics, aerospace |

Each welding method has its own pros and cons. The right choice depends on the specific requirements of the product. Selecting the correct welding method helps optimize production, improve product quality, and reduce costs. If you are unsure which welding technique is best for your product, contact PWP Solution for expert advice!

PWP Solution specializes in providing welding production lines and optimal welding solutions for major partners such as FORD and YAMAHA. We not only assist in installation but also provide tailored solutions to ensure the best quality for your products. By choosing PWP Solution, you gain access to expert consultation and welding solutions designed to achieve top-tier product quality!