Painting is a thin coating applied to the surface of materials to protect, decorate, and enhance the aesthetics of a product. In modern industry, painting is not merely about color—it also plays a crucial role in corrosion resistance, UV protection and extending the lifespan of equipment.

Today’s paints come in a wide variety, including water-based paints, solvent-based paints, and powder coatings, each tailored to specific technical requirements. Coating technologies are continuously evolving, aiming for greater environmental friendliness and improved performance. Choosing the right type of paint and appropriate coating process is a key factor in high-quality production.

With a highly experienced team in surface finishing, PWP Solution offers a wide range of solutions that meet international standards and customer-specific requirements—ensuring the highest product quality.

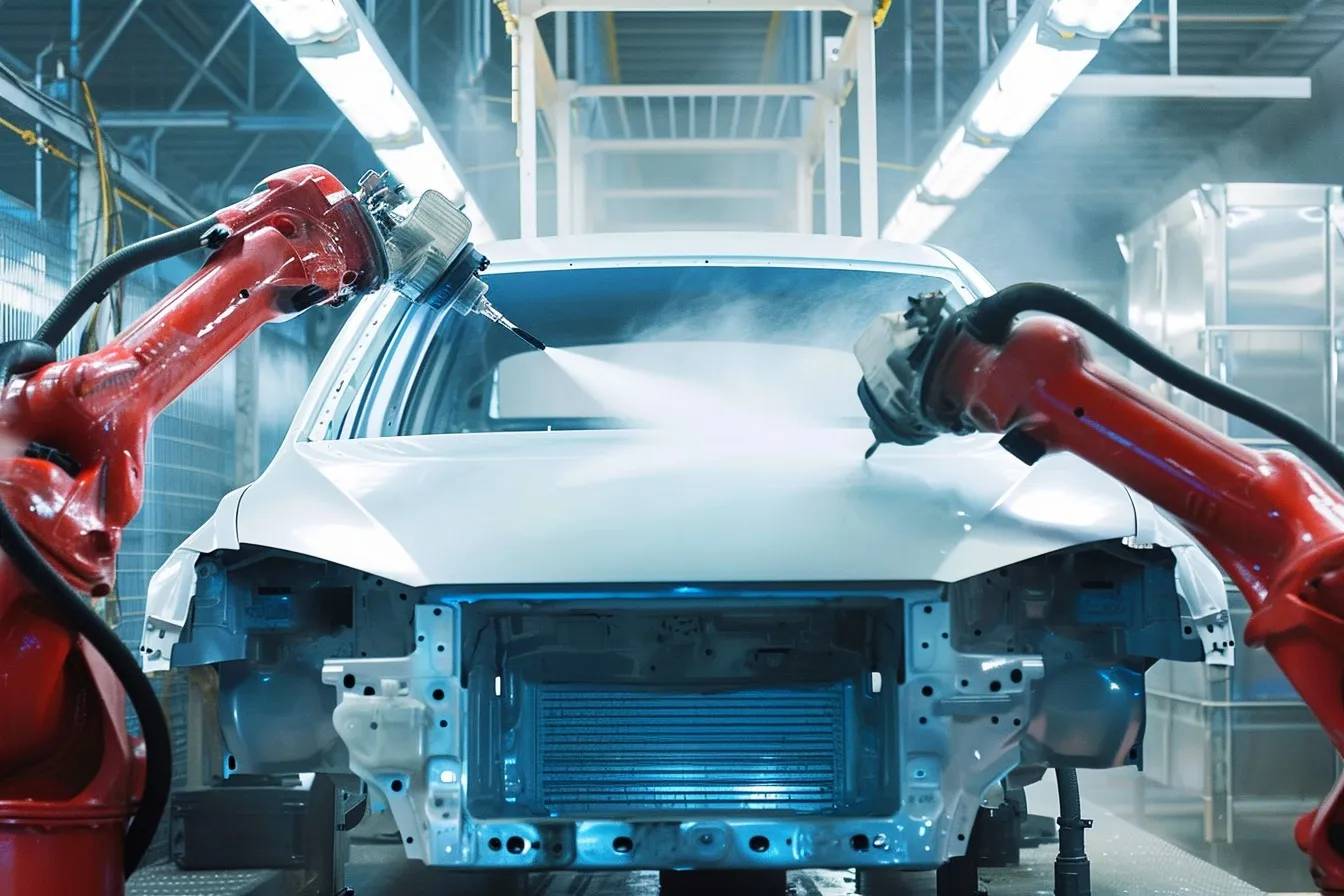

1. PWP Solution – Automated solutions for painting lines

-large.webp)

As a comprehensive provider of metal processing solutions, PWP Solution proudly offers professional surface finishing and painting services that meet all requirements in raw part processing.

At our painting facility, each product goes through a standardized process, from degreasing and cleaning to drying and final coating. Every step is carried out within a closed-loop system, ensuring strict quality control throughout.

Notably, technical parameters such as spray speed, spray duration, and paint volume are all monitored and flexibly adjusted via a computerized system. This not only optimizes product quality but also allows for quick adjustments for similar production batches, ensuring maximum efficiency and consistency.

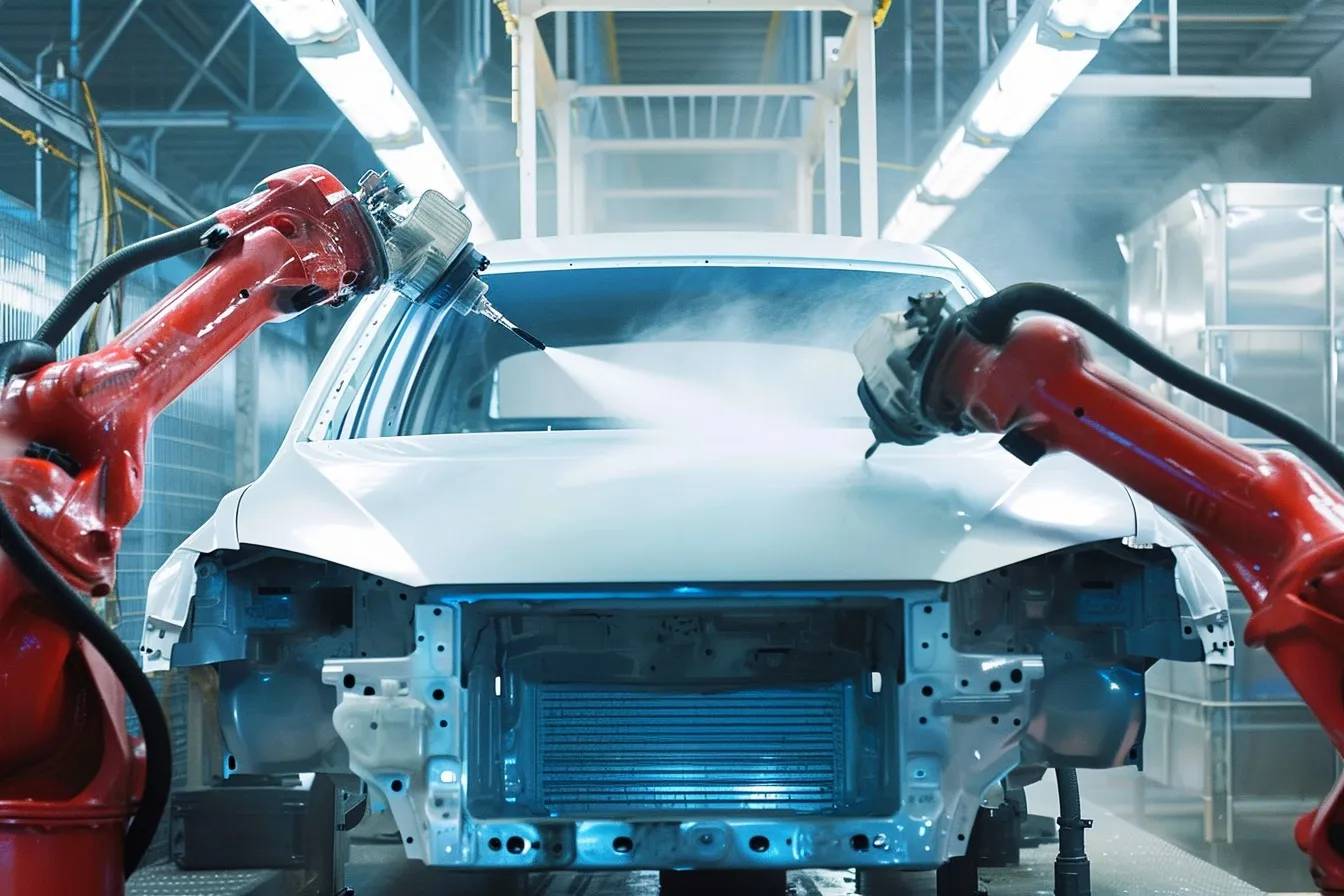

2. Automated painting line

.png-large.webp)

PWP Solution is equipped with a modern automated painting line that meets high-volume production demands with outstanding precision. The process is fully automated—from surface cleaning, drying, and paint spraying to final coating—ensuring uniformity and optimal quality for each product.

Key advantages of an automated painting line

An automated painting line is the optimal solution for businesses seeking to improve productivity and operational efficiency. Some outstanding benefits include:

-

Full automation, replacing manual labor.

-

Integration with robots to enhance production performance.

-

Computerized control of technical parameters, easily adjustable to meet requirements.

-

High-speed operation and accurate spraying reduce material waste.

Important considerations when investing in an automated painting line

While the advantages are compelling, businesses should keep in mind the following factors:

-

High initial investment costs, best suited for large-scale production.

-

Regular maintenance is required due to continuous high-frequency operation.

3. Semi-automated painting line

.png-large.webp)

For medium-scale production businesses, PWP Solution offers semi-automated painting line solutions. This system combines automation with manual operations, allowing flexibility in processing various products of different sizes and characteristics.

Benefits of semi-automated painting lines

Semi-automated systems can handle diverse spraying requirements, as both manual input and robotic programming can be tailored for specific products.

-

Reduces dependency on labor while maintaining operational flexibility.

-

Capable of handling different coating tasks with customizable programming.

-

Offers higher productivity and improved product consistency compared to manual methods.

4. The role of painting in mechanical processing

Applying advanced painting technologies not only enhances the appearance of products but also improves durability. Key benefits include:

-

Enhancing product aesthetics.

-

Improving corrosion resistance to extend product lifespan.

-

Increasing electrical conductivity in electronic components.

-

Reducing friction and improving wear resistance for smoother operation.

5. Painting methods used by PWP Solution

5.1. Sandblasting/Shot blasting

- This is one of the most widely used surface finishing techniques today due to its ability to operate at high speed without affecting the product's surface or structure.

- The method uses fine abrasive particles sprayed at high velocity to clean the surface. This helps to polish or texture the surface and remove scratches, rust, dirt, and other residues.

5.2. Powder coating

This method involves applying electrostatically charged dry powder to a product’s surface and melting it to create a durable and uniform finish. Compared to traditional liquid paint, powder coating offers several key advantages:

-

Strong adhesion to surfaces, resulting in high durability even in harsh environments.

-

Enables workers to easily coat complex corners and hard-to-reach areas.

4.3. Electropolishing

Electropolishing is a surface finishing process that uses electrochemical reactions to remove a thin layer of material from a metal surface, leaving it smooth and shiny.

Advantages of electropolishing:

-

Easily removes contaminants and surface residues.

-

Leaves the surface clean, glossy, and visually appealing.

6. Why choose PWP Solution’s painting lines?

With years of experience in mechanical processing and production automation, PWP Solution is committed to delivering optimal solutions that improve both productivity and product quality. We offer:

-

Consultation to provide tailored solutions for your specific production needs.

-

Supply of modern, high-quality equipment and painting lines.

-

Reliable maintenance and technical support to ensure long-term system performance.

7. Conclusion

Painting technology not only optimizes costs but also ensures consistent and durable product quality. With its strong growth potential, painting will remain a vital solution in enhancing production capacity and competitiveness. If you’re looking to invest in painting line equipment to boost your business's productivity, don’t hesitate to contact PWP Solution for timely and professional support!

-large.webp)

.png-large.webp)

.png-large.webp)

.png-large.webp)

-large.webp)

.png-large.webp)

.png-large.webp)