Welding is a method used to join metal or non-metal parts by heating the joint area to a welding temperature. The molten or softened material, combined with pressure or filler material, solidifies to form a durable bond known as a weld joint.

Each application may require a different welding technique, so understanding each method is essential. Below are the most widely used welding methods:

Arc welding: Utilizes electric current to generate an arc that melts the metal for joining.

Fusion welding: Involves heating the edges of the metal to a molten state while adding filler material to fill the gap between the two parts, forming a solid weld upon cooling.

Pressure welding: The metal at the joint edges is heated to a plastic state and then pressed together to form a weld.

Thermite welding: Uses chemical reactions to generate intense heat that melts the joint edges, often combined with pressure to create a solid bond.

Thanks to its ability to create strong bonds and allow for flexible shaping, welding plays a crucial role in both daily life and industrial manufacturing. Its applications include:

Manufacturing and mechanical fabrication: Widely used in machinery production and metal fabrication for components such as machine bodies, frames, bolts, screws, etc.

Construction: Commonly used in steel structures and infrastructure such as welding beams, columns, bridge components, and rail tracks.

Repair and maintenance: Used to restore broken or worn parts and reinforce damaged structures.

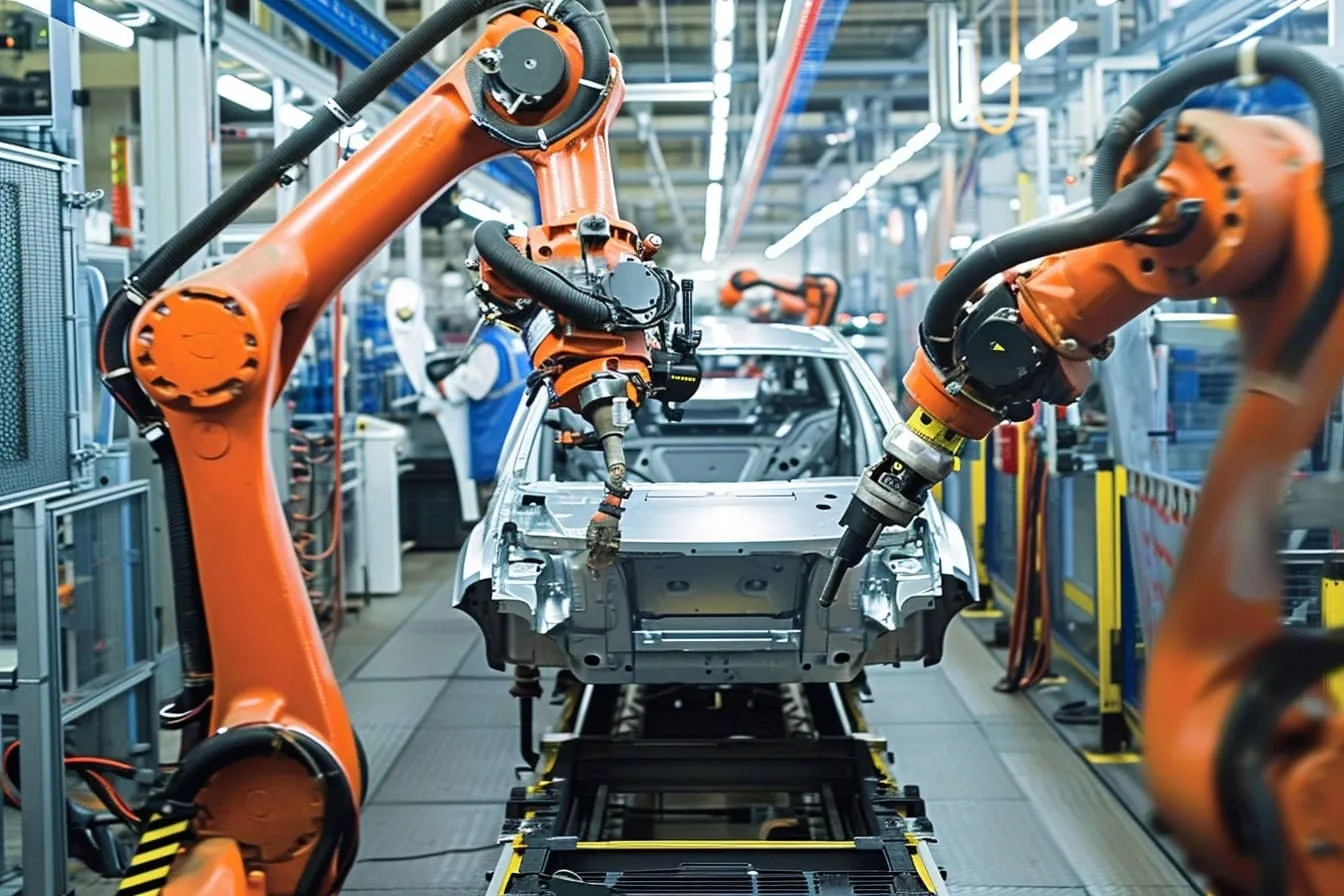

In addition to manual welding, PWP Solution also integrates robotic welding into production lines to enhance precision and productivity for businesses.

Robotic welding, considered an automated method, is increasingly preferred by manufacturers due to its convenience. The entire process is programmed and controlled via computer systems, supported by skilled operators.

Operators can easily adjust coordinate parameters as needed, with all settings recorded and managed through dedicated software.

A major advantage of robotic welding is its high degree of automation. While one part is being welded, the next workpiece can be prepared, ensuring a continuous workflow. Completed components are replaced with the next items in line, seamlessly integrated with the robot’s control system.

Robotic welding is developed based on the principles of manual welding but is optimized through precise programming to improve efficiency and product quality. Here are the key differences:

| Manual welding | Robot welding |

| - Relies heavily on the experience and skills of workers. | - Delivers consistent, high-precision results, suitable for both simple and complex products. |

| - Higher risk of accidents and health issues due to harsh working environments. | - Operates continuously 24/7, handles hazardous tasks, and endures harsh conditions. |

| - Product consistency may vary within the same project. | - Minimizes defects and deformation, ensuring top product quality. |

| - Cost-effective and requires minimal equipment, suitable for small-scale production. | - Requires specialized facilities, advanced technology, and trained technicians. |

PWP Solution specializes in advanced metal processing, welding products, and welding components, ensuring the ability to handle a wide range of mechanical parts from simple to highly complex.

With a team of professionally trained engineers experienced in large-scale projects, PWP Solution guarantees that every product delivered to customers is of the highest quality and value.

Welding is not only a technique for connecting metal components but also a sustainable and essential solution across various industries. It enhances product quality and boosts competitiveness for businesses. In today’s era of industrialization and automation, welding can be integrated with other methods to form fully automated production lines, reducing reliance on manual labor.

If you’re looking for welding solutions tailored to your products, don’t hesitate to contact PWP Solution for timely consultation and a detailed quotation!